Tata Steel’s Kalinganagar and Meramandali plants receive Responsible SteelTM Certification

By Payal Banarjee

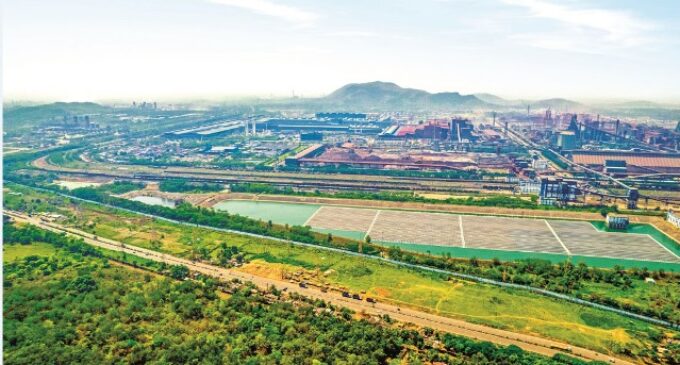

Mumbai, Feb.9: Tata Steel continues to lead the way in sustainable steel production as its Kalinganagar and Meramandali plants receive the prestigious Responsible SteelTM Certification.This marks a significant milestone in the Company’s sustainability journey, following Jamshedpur’s historic achievement as the first Indian steel plant to receive the certification in 2022. In India,Tata Steel now has more than 90% of its steel production from Responsible SteelTM certified sites.

Three facilities in Jamshedpur –Steel Works, Tubes Division, and Cold Rolling Mill (Bara) were awarded the certification in October 2022.The inclusion of Kalinganagar and Meramandali plants reaffirms the Company’s dedication to responsible business practices and environmental stewardship.

ResponsibleSteelTM is the steel industry’s first global multi-stakeholder standard and certification initiative that works with steel producers, consumers, and intermediaries towards building a sustainable steel industry by addressing pressing challenges including climate change, diversity, human rights, and more.

T. V. Narendran, CEO & MD, Tata Steel,said:”The ResponsibleSteel Certification for our sites is a testament to Tata Steel’s unwavering commitment to sustainability. It reflects our proactive approach towards addressing the evolving challenges of the steel industry and shaping a better tomorrow. I sincerely appreciate the ResponsibleSteel team, the auditors, the assurance panel, and the team at Tata Steel for their efforts in achieving this milestone. We are progressing well towards our target of certifying all our existing steelmaking sites in India by 2025.”

Annie Heaton, CEO of ResponsibleSteel commented, “With the audit process for these two new site certifications, Tata Steel has demonstrated its commitment to openly progress its social and environmental responsibilities. During the audits, both sites’ GHG emissions reduction strategies and water stewardship programmes were highlighted for their robustness. The ResponsibleSteel Standard goes further, beyond managing a site’s environmental impacts, and aims to support sites to ensure the wellbeing of the site’s workers and local communities.”

Annie continued, “Tata Kalinganagar has demonstrated continued determination to work with the community following a history of protests and the relocation of local people, working to provide quality housing and improved health and education through the Tata Steel Medica Hospital and the Loyola School. Likewise, interviews with a range of external stakeholders at the Meramandali site pointed to the commitment of the site to the community and workers reported improved health and safety procedures following Tata’s acquisition of the site. Steelmaking is a complex and often hazardous process, and the site and the company’s commitment to continuously bettering health and safety to mitigate future risk is well noted. Overall, the auditors were encouraged by the continued progress both sites are committed to making through the ResponsibleSteel certification programme.”

Tata Steel was the first member of Responsible SteelTM from India and is undergoing assessment under the Responsible Steel™ framework for its various sites. The Responsible Steel™ certification process involves a detailed review of key policies and the working for the site by an independent external assessor.